The elevator swallows 3,000 yuan of electricity every day. These companies urgently need to upgrade their energy-saving solutions

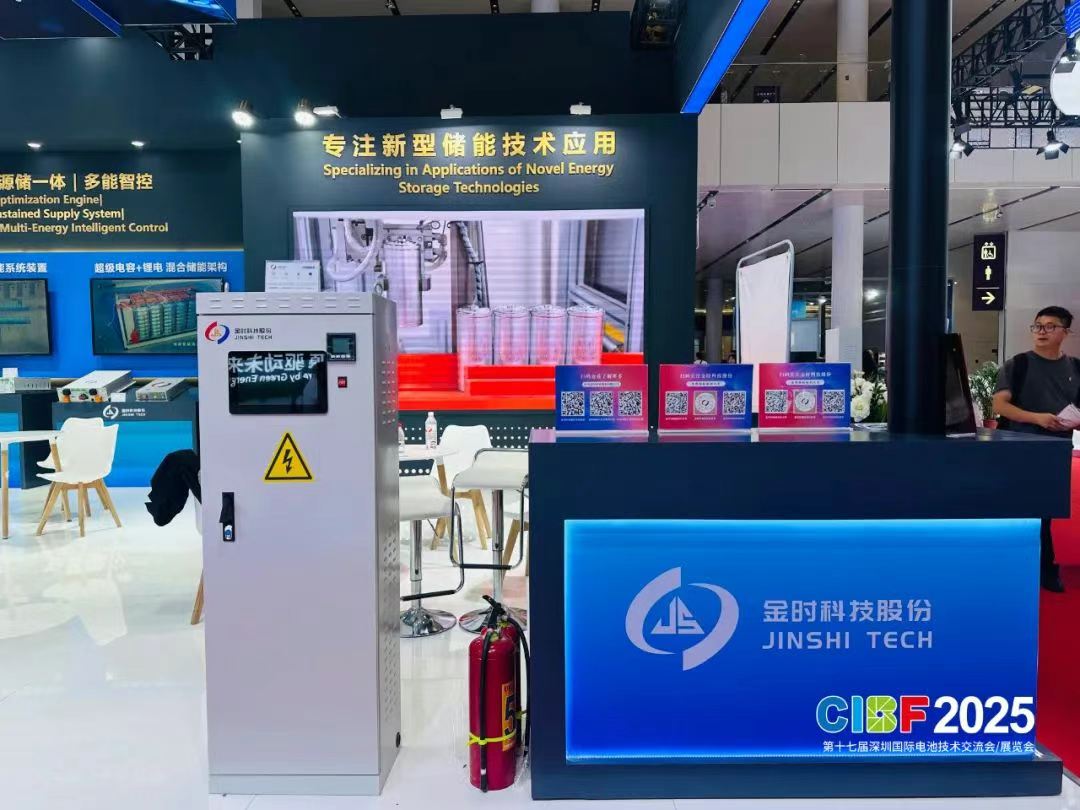

Intheenergyconsumptionofurbanbuildings,theproportionofelevatorelectricityconsumptionisashighas10%-15%,especiallyinhighfrequencyusescenariossuchascommercialcomplexes,hospitals,hotels,etc.,theelectricityexpenditurecausedbyenergywasteoftraditionalelevatorscontinuestorise.SichuanJinshiTechnologyCo.,Ltd.supercapacitorelevatorenergysavingdevice,basedontheself-patentedenergy-feedbacktechnology,helpsenterprisesachieve the dualbenefitsofenergyconsumptioncostoptimizationandequipmentlifeextensionthroughefficientrecoveryofelevatorbrakingenergy.

Whyelevatorenergyconsumptionhasbecomean"invisiblecostblackhole" for enterprises

During the operation of ordinary traction elevators, 30%-40% of the electrical energy is converted into heat dissipation through braking resistance, which not only causes waste of energy, but also causes the temperature of the machine room to rise and accelerate the aging of electrical components. Traditional energy-saving solutions, such as feedback grid installations, have three major limitations:

Response delay: There is a lag in the energy exchange between the inverter and the power grid, which affects the smoothness of the elevator operation;

Harmonic pollution: inferior feedback equipment is easy to cause harmonic interference in the power grid and threaten the safety of other precision instruments;

Complex maintenance: Filter components need to be replaced regularly, increasing labor and spare parts costs.

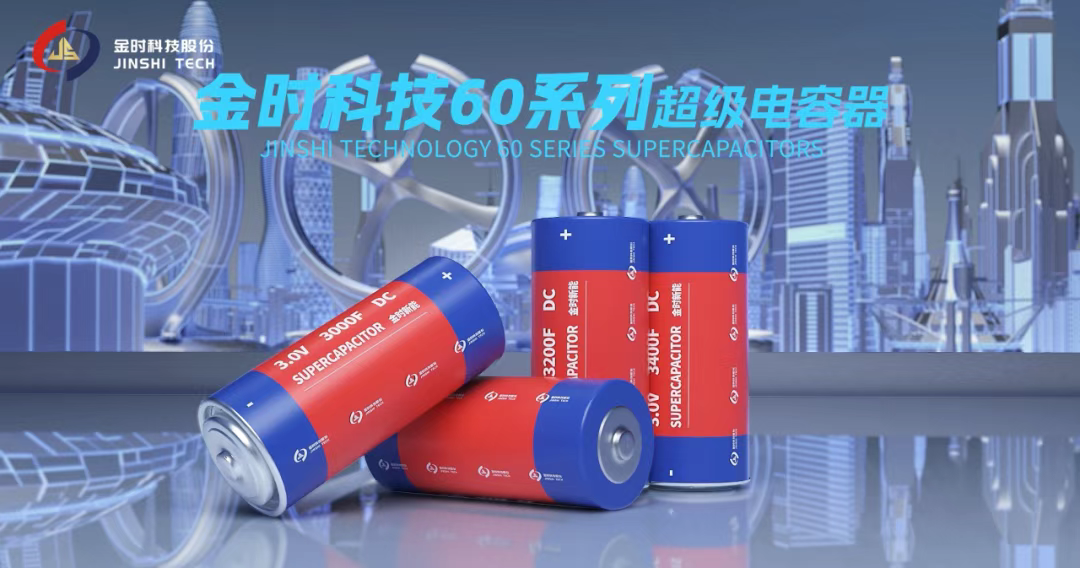

Howsupercapacitorsreconstructelevatorenergyflow

Sichuan Jinshi Technology Co., Ltd. supercapacitor elevator energy-saving device adopts the closed-loop energy-saving mode of "real-time energy storage-on-demand release" to break through the bottleneck of traditional technology:

Millisecond-level dynamic response

The builtin highpowerdensity supercapacitor module can capture more than 97% of the regenerative power at the moment of elevator braking, and release it accurately when the elevator starts, reducing the power draw of the power grid.

Pure physical energy storage, zero harmonic risk

Different from the power feedback grid technology, supercapacitors store/discharge through the principle of physical polarization, without inverter process, completely eliminate harmonic pollution, and meet the needs of sensitive scenarios such as hospitals and laboratories.

Wide temperature and long life design

The device operates stably from -25°C to 65°C, with a cycle life of more than 1 million times (about 15 years), and the fully sealed structure design eliminates maintenance operations such as dust removal and electrolyte replacement.

These companies urgently need to upgrade their energy-saving solutions

Commercial real estate

Pain points: Elevators in shopping malls and office buildings run nearly 100 times a day, and the cost of electricity accounts for 20% of the total property expenditure;

Value: A single elevator saves 1520 kWh of electricity (measured data), calculated according to 1.2 yuan/kWh, the annual electricity cost is saved by more than 6,500 yuan, and the payback period is < 3 years.

Public hospitals

Pain points: Surgical ladders and hospital bed ladders need to run at high frequency for 24 hours, and traditional resistor heat dissipation aggravates the load of air conditioning;

Value: Energy recovery reduces the temperature of the computer room by 35°C, reduces the energy consumption of air conditioning by 10%, and simultaneously extends the life of the control system by 30%.

Industrial logistics park

Pain points: freight elevators start and stop frequently, and the failure rate of braking resistance accounts for 40% of the total elevator repair volume;

Value: The supercapacitor device reduces the braking resistance loss by 80%, and the annual maintenance cost is reduced by more than 12,000 yuan.

Use data to validate energy savings

Take a medium-sized commercial complex (equipped with 20 elevators with a load of 1600kg) as an example:

Before the transformation: assuming that a single elevator consumes 85 kWh of electricity a day, the total annual electricity cost = 85 kWh×20 units× 365 days× 1.2 yuan/kWh≈ 745,000 yuan;

After the transformation: the energysaving rate is calculated at 22%, and the annual electricity saving fee = 745,000 yuan× 22% ≈ 164,000 yuan;

Maintenance cost: The maintenancefree design of the supercapacitor device reduces the replacement cost of braking resistance by about 30,000 yuan per year;

Comprehensive income: The total cost of project transformation is 450,000 yuan, the static investment payback period is ≈ 2.7 years, and the net income during the equipment life cycle exceeds 2 million yuan.

(Note: The above data refer to the "Technical Specification for Elevator Energy Efficiency Testing" (GB/T 39172-2020) and the average measured value of the industry, and the specific value fluctuates slightly due to the elevator working conditions and electricity price policy.)

Sichuan Jinshi Technology Co., Ltd. supercapacitor energy-saving series devices have passed the safety, energy efficiency and adaptability certification.

Independent technical barriers: master the whole chain of patents from capacitor materials, module balancing to system integration;

Fullscene adaptation: provide customized solutions for 800kg5000kg load elevators, and adapt to new elevators and old elevators; Full coverage of the service network. At the moment when electricity prices continue to rise and the "double carbon" policy is strongly constrained, the energysaving transformation of elevators has changed from "optional" to "mandatory". The energysaving device of supercapacitor elevator of Jinshi Technology helps enterprises reduce costs and increase efficiency with quantifiable energy-saving data and reliability verified by more than 1,000 projects.