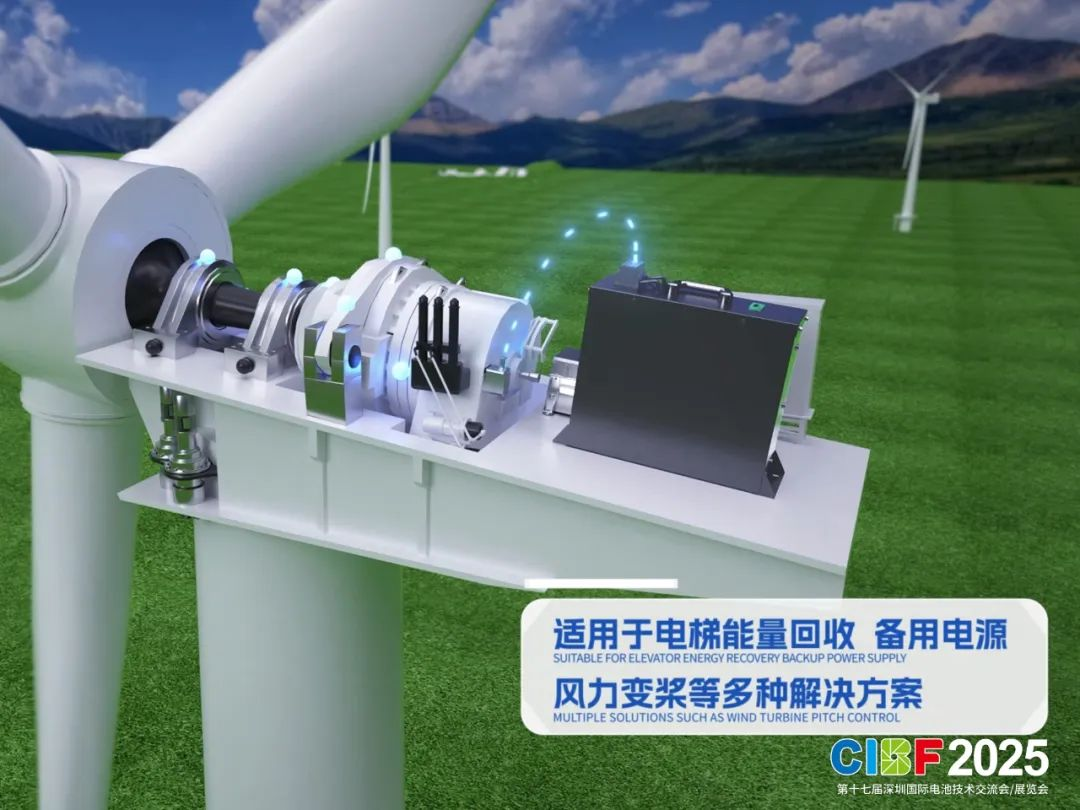

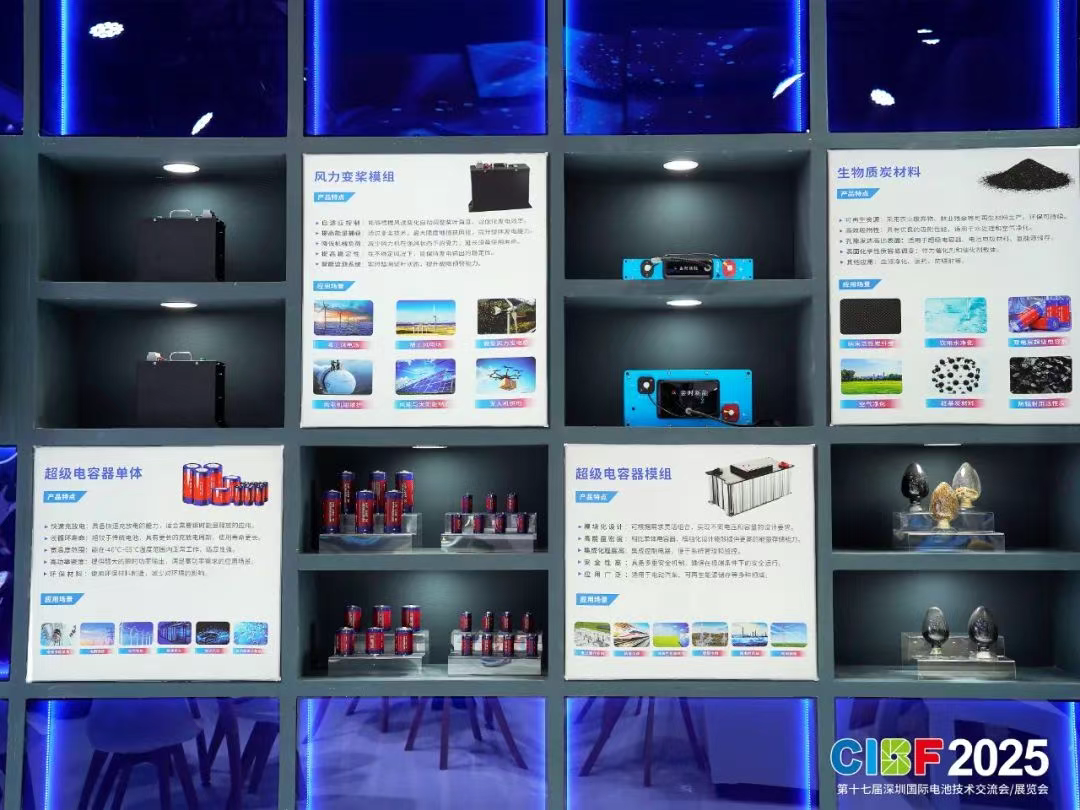

Supercapacitors enable wind power pitch systems: creating highly reliable, maintenance-free green power solutions

Astheglobalenergystructureacceleratesthetransitiontoacleanerone,windpowergeneration,asoneofthemainrenewableenergysources,isfacingstringentrequirementsforhigherefficiencyandloweroperationandmaintenancecosts. In the pitch system,the core control link of wind turbines,traditional lead-acid batteries,lithium batteries and other energy storage equipment are gradually difficult to meet the needs of new high-power wind turbines due to problems such as insufficient response speed,low temperature performance attenuation,and high maintenance costs.ThepitchsupercapacitorsystemindependentlydevelopedbySichuanJinshiTechnologyCo.,Ltd.(hereinafterreferredtoas"JinshiTechnology")solvesthepainpointsoftheindustrywithtechnologicalinnovationandprovidesasafer,morestableandmoreeconomicalpowerguaranteesolutionforthewindpowerindustry.

Howsupercapacitorsarereshapingwindpowerpitchsystems

The pitch system is the "safety brain" of the wind turbine, and its core task is to adjust the blade angle in real time according to the change of wind speed, ensure the stable operation of the wind turbine within the rated power, and urgently retract the blade to avoid danger in extreme weather. Due to the slow charging and discharging rate and short cycle life, traditional energy storage equipment can easily lead to pitch delay or failure, which threatens the safety of the unit. Sichuan Jinshi Technology Co., Ltd. supercapacitor pitch energy storage system has achieved breakthroughs based on the following technical advantages:

Millisecond-level response to ensure safety under extreme working conditions

The highpower density supercapacitor module can release peak power in 0.5 seconds, accurately respond to sudden gusts of wind or grid fluctuations, and ensure that the pitch motor can quickly perform angle adjustments to avoid fan overload or mechanical damage.

Wide temperature range operation, no fear of harsh environments

The supercapacitor can still maintain more than 95% capacity output in the environment of -40°C to 65°C, which completely solves the problem of the performance of traditional batteries in lowtemperature areas and easy thermal runaway in hightemperature environments, and is suitable for complex wind fields such as offshore, high altitude and extreme cold.

The whole life cycle is maintenance-free, reducing costs and increasing efficiency

The cycle life of the system exceeds 1 million times, the design life is synchronized with the main body of the wind turbine (more than 25 years), there is no need to replace the battery frequently, and the average annual operation and maintenance cost of a single fan is reduced by more than 30%.

From onshore to offshore, covering diverse needs

Large onshore wind farms

In view of the large temperature difference between day and night and frequent fluctuations in wind conditions in inland areas, supercapacitors stabilize the voltage of the pitch motor through instantaneous power compensation, reduce the shutdown accidents caused by transient fall of the power grid, and increase the power generation by 5%-8%.

Offshore wind clusters

In the high humidity and high salt spray environment at sea, the corrosion of metal parts is accelerated, and Jinshi Technology adopts fully sealed IP68 protection design and anticorrosion coating technology to ensure the longterm reliable operation of the system in the harsh marine climate and reduce the frequency of operation and maintenance ships.

Renovation of old units

It provides an upgrade kit of "Supercapacitor Intelligent Management System" for existing wind farms, which is compatible with mainstream pitch controller interfaces, and the system response speed is increased by 3 times after the transformation, helping to extend the service life of old wind turbines.

Upgrade the entire chain from security to revenue

Safety closed-loop: Through real-time monitoring of capacitor health status and linkage with pitch logic, fault prediction and active protection are realized, and the failure risk of the pitch system is reduced to less than 0.01%.

Power generation efficiency: Reduce the power rationing loss caused by the delay of the pitch, and the average annual increase in income is more than 200,000 yuan based on the calculation of a single 5MW wind turbine.

Low carbon footprint: The carbon emissions of supercapacitors are reduced by 60% compared with lithium batteries, and 100% recycling is supported, contributing to the goal of zero carbon in the whole life cycle of wind farms.

In the process of the wind power industry moving towards the era of parity and the goal of zero carbon, Jinshi Technology's supercapacitor pitch energy storage system redefines safety standards with hard-core technology, and empowers customer value growth with reliability and economy. We sincerely invite industry partners to explore the infinite possibilities of clean energy innovation!