Jinshi Technology debuted at the 2025 CIBF Shenzhen Battery Exhibition: knocking on the door of the future of green energy with technological innovation

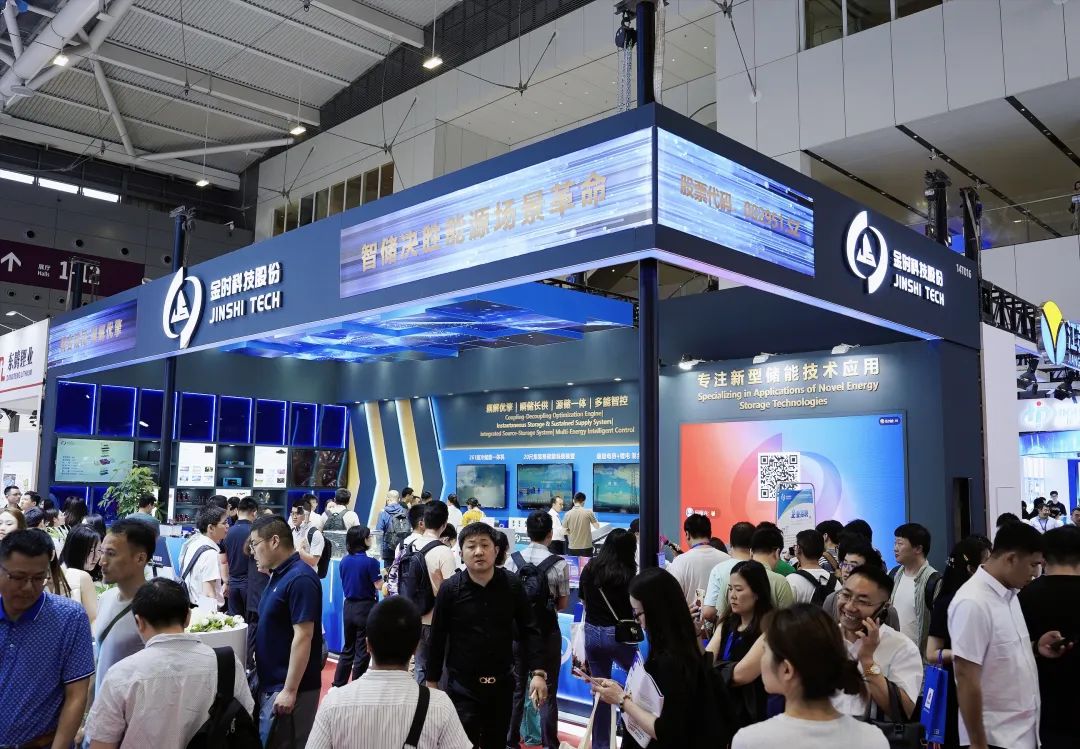

On May 15, 2025, the 17th Shenzhen International Battery Technology Exchange Conference kicked off here, and the eyes of the global new energy field gathered here. In this grand event of the collision of technology and ideas, Sichuan Jinshi Technology Co., Ltd. (stock code: 002951. SZ) (hereinafter referred to as "Jinshi Technology") and its subsidiary Sichuan Jinshi New Energy Technology Co., Ltd. (hereinafter referred to as "Jinshi New Energy") made their debut as a new energy enterprise for the first time (Booth No. 14T016). From supercapacitors to coupled energy storage, from material breakthroughs to safety revolutions, the company's booth was like a window, showing the industry a clear path from traditional manufacturing to green technology.

Strategic transformation: a green breakthrough that has been accumulating for five years

Back in 2019, when the new energy wave began to appear, Jinshi Technology opened the prelude to strategic transformation. The company, which has been deeply involved in traditional fields, keenly seizes the opportunity of the era of carbon neutrality goals, and invests its core resources in the research and development of supercapacitors, energy storage systems and materials. This transformation is not accidental, but a precise planning around the layout of the whole industry chain of "materialmaterialdeviceuse"from the basic research and development of electrode active materials, to the integrated application of module systems, to the indepth adaptation of terminal scenarios, every step directly points to the pain points of the industry.

In 2021, with the establishment of its subsidiary Jinshi New Energy, the company took a key step: through the industry-university-research cooperation with the team of Professor Yang Weiqing of Southwest Jiaotong University, it successfully broke through the technical barriers to the localization of supercapacitor electrode materials and pushed the product performance to the international leading level. The acquisition of Qianye Technology in 2023 will inject new momentum into the field of energy storage security, forming a technical closed loop of "source-storagecontrol" trinity. After five years of sharpening the sword, this transformation is not only a shift in business focus, but also a transformation of identity from "follower" to "definer".

Technology Matrix: The "Triple Key" to Solve the Energy Storage Dilemma

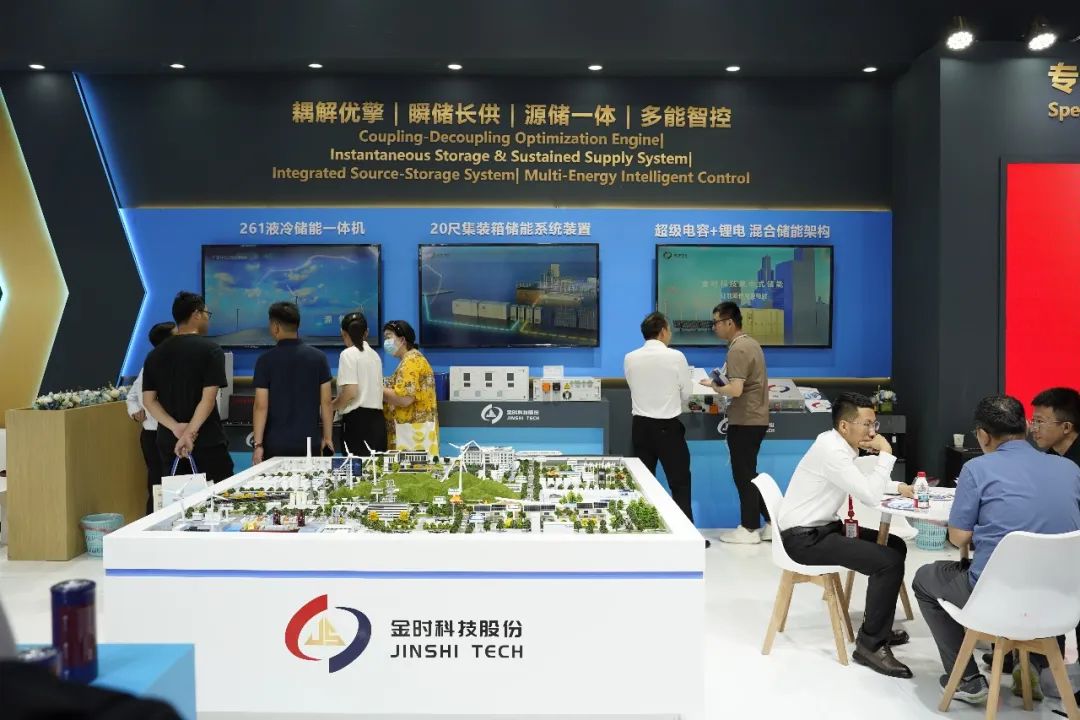

Walking into booth 14T06, the three major technological achievements have built the innovation map of Jinshi Technology. They are like gears that bite each other, driving a double leap in energy storage efficiency and safety.

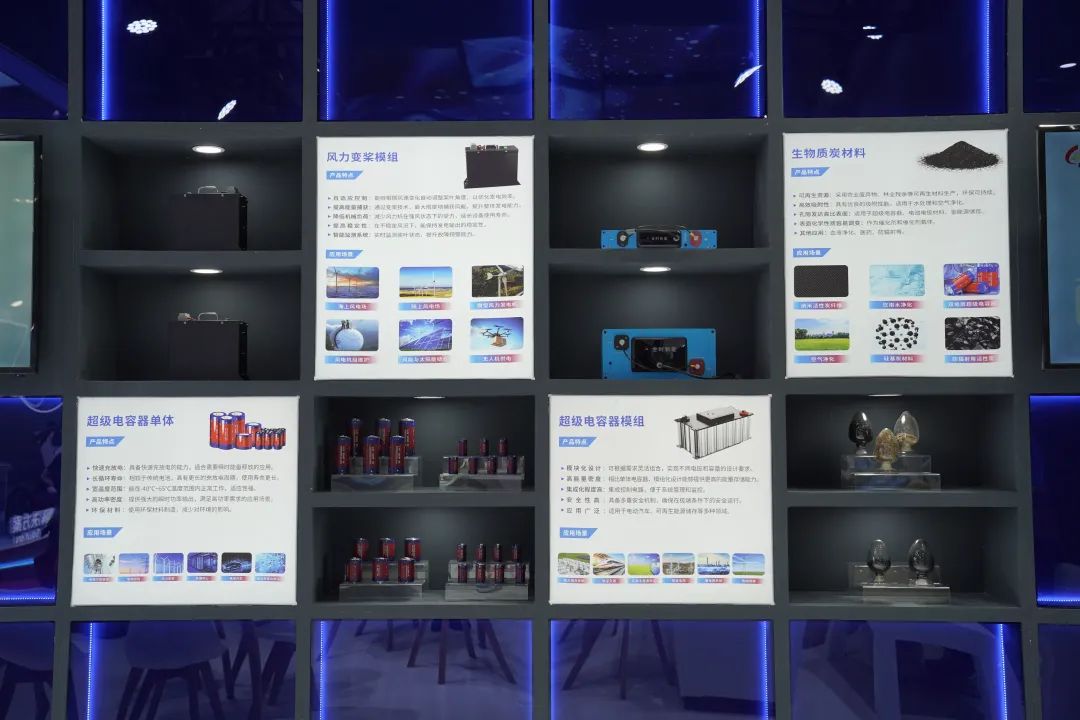

The first key: the "efficiency revolution" of supercapacitors

The supercapacitor monomers displayed at the booth have the characteristics of high power density, wide temperature range, long cycle life, etc., and behind their internal resistance as low as 0.18mΩ, it is a breakthrough in the microstructure of electrode materials. Compared to the industry average, a 5% deviation in capacity consistency means that the grid frequency modulation response speed is improved and the equipment life is extended. From the instantaneous power compensation of wind power pitch systems to the precise control of elevator energy feedback, these "energy regulators" are redefining the energy storage logic for short-term high-power scenarios.

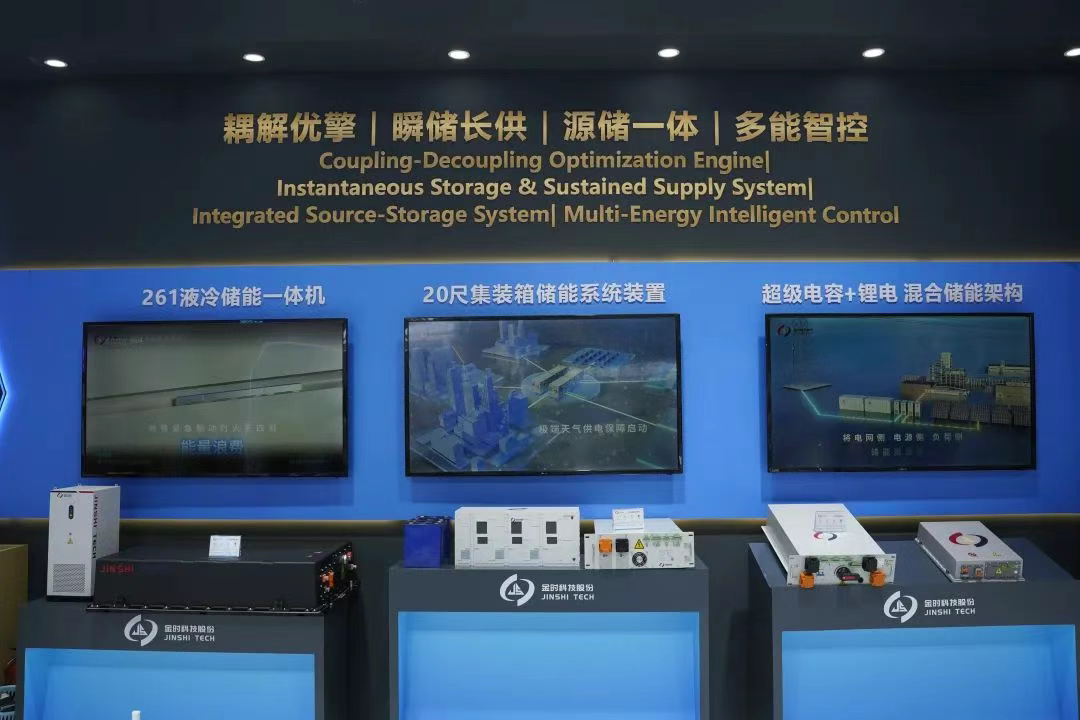

Thesecondkey:the"space-timeequilibrium"ofcoupledenergystorage

When the second-level response of supercapacitors meets the long-term battery life of lithium batteries,how to achieve complementary advantages?The 1.25MW/5MWh container system in the center of the exhibition area provides the answer.Through the original "power-time"two-dimensional decoupling algorithm,the system can intelligently distribute the output ratio of the two technologies,and push the cycle life to millions of times while improving the frequency modulation efficiency.Thesupportingliquidnitrogenfireprotectionschemeisevenmoresubversive-5secondstoturnto"activeintervention".

The third key: the "natural gift" of biochar

On one side of the booth, carbon materials made from renewable resources such as coconut shell and ramie quietly reveal the ecological logic behind the technology. These highperformance materials derived from nature not only reduce the carbon footprint of supercapacitors, but also open up the circular chain of "agricultural waste-high valueadded materialsgreen energy storage equipment". Here, technological innovation and sustainable development resonate at the same frequency.

Industry-University-Research Integration: From Laboratory to Industrialization

"The real technical barrier comes from the reverence for basic science." In the booth technology salon, a sentence from the person in charge of R&D expressed the logic of innovation. The indepth linkage between the company's core R&D team and the laboratory of Southwest Jiaotong University has built a "theorypractice" transformation channel. On the fully automatic module production line with an annual output of 2.4GWh, the nanoscale material preparation process and the AI quality inspection system work together to transform the formulas in the paper into actual products.